- Home

- Manufacturing Competence

About us

Bringing vehicles to life since 1986

VE Commercial Vehicles, one of the India’s leading manufacturers of trucks and buses, has always spearheaded the Future of Indian Trucking with the next-gen vehicles and innovative support solutions. Through every vehicle that we produce we help achieve people their dreams, ambitions and ensure they or their products reach their destination safely and on time. We understand the importance of trucks and buses, and how integral they are to keep the country running. Every day with relentless pursuit of perfection and exceptional quality, these vehicles are brought to life in state of the art VECV’s facilities.

Pithampur Plant

Eicher Trucks and Buses completed 34 years of operations in India in the month of June 2020. The first Eicher truck was rolled out from its manufacturing plant in Pithampur, Madhya Pradesh in 1986 and over the past years, the products have got endorsement from hundreds of thousands happy customers. The plant is spread over 87 acres of land with current installed capacity of 90,000 vehicles per annum, producing over 1000 vehicles per acres.

- Highly flexible, lean, and agile environment delivering high quality trucks, Engines and bus Chassis

- Smart factory with right blend of automation, produces 1000 vehicles per acres.

- Certified for Integrated Management System – encompassing Quality, Health & Safety, Environment and Energy Management system

- Volvo Production System as base for Manufacturing Operation

- The plant has a fully equipped vehicle and engine development center with fatigue lab, complete virtual vehicle integration capability and Simulation Lab

Bhopal Plant

To expand further and cater to dynamic market requirements and evolving customer needs, the Bhopal facility was initiated in November 2019. In less than a year, the assembly of first engine was rolled out in November 2019 from the new plant. The new facility will be utilized to manufacture VECV’s Pro2000 light duty BSVI range. Manufacturing plant in Bhopal spread over 147.8 acres of land and has an initial capacity of 40,000 trucks per annum, which would be scalable up to 100,000 per annum to align to future business plan volume requirements.

- Advance Powertrain & Vehicle assembly lines (BSVI compliant) with right blend of automation and frugal approach.

- Integrated Management System (IMS) and compliant to Industry 4.0.

- Lean and efficient material management from next door major ancillaries & Vendor managed warehouse.

- Green initiatives for sustainability – Zero discharge, Water conservation, Daylight & Rain water harvesting.

Baggad Plant

To capitalize on the opportunity of improved road infrastructure and growth of smart cities, an ultra-modern bus body manufacturing facility was set up at Baggad (Madhya Pradesh) in September 2013. The plant is spread over a huge expanse 43 acres has a current installed capacity of 15,600 per annum, expandable to 19,200 per annum.

- The multi-model plant which manufactures Light, Medium and Heavy duty buses in Diesel ,CNG & EV’s

- First of its kind bus plant which is equipped with high tech robotic paint system using wet on wet epoxy & PU painting from same robot.

- Certified for Integrated Management System – encompassing Quality, Health & Safety, Environment and Energy Management system

- Volvo Production System as base for Manufacturing Operation.

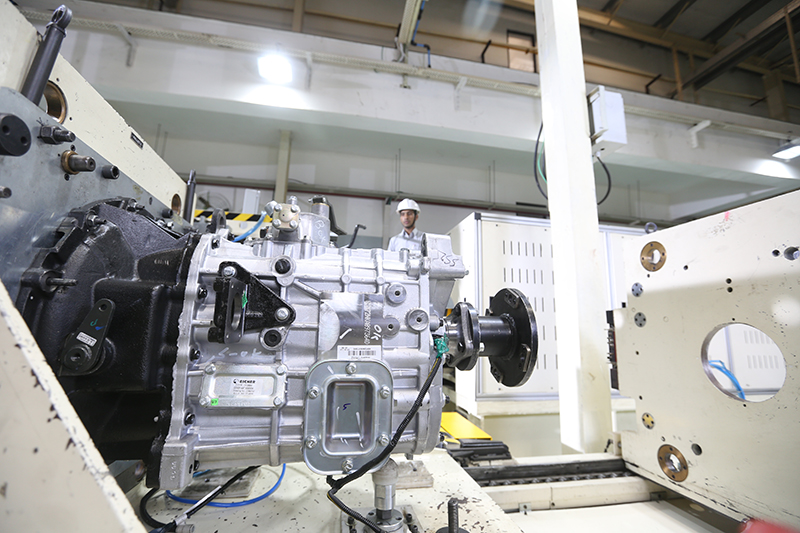

VE Powertrain

VE Powertrain is the engine hub of VECV that started operations in India in 2013 and caters to the engine requirements of Volvo Group across Europe and Asia. VE Powertrain (VEPT) is technologically the most advanced engine manufacturing plant in India where commercial production and is spread across over 10 acres. The current capacity stands at 75,000 units which is scalable to 100,000 with additional investments. Over 1,65,000 engines have been manufactured at the plant as of March 2020.

- VEPT is a global hub for meeting the medium-duty engine requirements of Volvo Group globally for five- and eight-litre engines

- Plant is Gold Certified for Volvo production System (VPS), Bench mark in Cleanliness with in Volvo Group

- Certified for Integrated Management System – encompassing Quality, Health & Safety, Environment and Energy Management system

- VECV had more than 7 years of experience in manufacturing and supplying base engines for Euro VI requirements to the Volvo Group.

- VECV has incorporated all the learnings in the development process of BS VI engines in India. Further, BS VI development is also completed and VEPT is ready to cater to new BS VI emission norms in India.

HOSAKOTE FACILITY

Volvo Buses set up India’s first complete bus manufacturing facility in 2008 comprising a state-of-the-art bus assembly plant with end-to-end capabilities. The facility can roll out of up to 2,000 units annually on a two-shift basis. The offerings range from chassis to customised fully built buses that are directly delivered to customers.

- Given its integrated and flexible nature, the plant can undertake the manufacture of multiple products on the same line with minimum adjustments.

- Most assembly operations are uniquely designed to offer a high degree of repeatability and reproducibility.

- Volvo Buses India (VBI) has consistently imbibed best practices and processes from Volvo Buses’ global manufacturing operations.

- A comprehensive skill development centre ensures that the manufacturing workforce stays well-ahead of the learning curve.

Eicher Engineering Components (EEC)

Eicher Engineering Components (EEC) is one leading Transmission, Aggregate and Component Business of VE Commercial Vehicles Limited. EEC came into existence in 1992 in a take-over of a Unit in Mumbai which was the first commercial gear manufacturing facility in India in the auto-ancillary sector. In the ensuing years, EEC has grown from strength to strength and is one of the leading Transmission, Engine and Axle components and aggregates manufacturers in India. EEC has customers across the globe and is strategic supplier to large OEMs like Volvo, Caterpillar, John Deere, Mahindra etc besides meeting the captive requirements of Eicher Trucks and Royal Enfield.

Dewas Plant

Located in Central India in the industrial area of Dewas, Madhya Pradesh, India, the set-up is spread over approximately 30 acres, with another around 16 acres’ land available for future expansion. The state of art plant houses the latest technology in various processes for gear manufacturing, Crown wheel Pinion, Bevels and transmission assembly.

- Is one of the largest commercial gear manufacturing plants in India for Gear Grinding and Heat Treatment

- Has an exclusive New Product Development cell for expedited new product introductions

- Has an advanced and state-of-the-art Transmission Assembly line, running on MES (Manufacturing Engineering Systems)

- Certified to various systems for Quality & Environment Management and for Employees Health & Safety – IATF16949:2016, ISO 14001:2015, OHSAS 18001:2007

SEZ Pithampur Plant

Located in the Special Economic Zone of Pithampur, Madhya Pradesh, India, the plant has a total area of 9.4 acres. The constructed area is around 1 acre with around 8 acres available for future expansion. The plant manufactures diverse variety of auxiliary gearboxes and aggregates for global customers

- Equipped with different assembly lines for light duty, medium duty and heavy duty aggregates, wet-on-wet painting facility and end-of-line testing and rig testing facilities

- Certified to various systems for Quality & Environment Management and for Employees Health & Safety – IATF16949:2016, ISO 14001:2015, OHSAS 18001:2007